The three little nylon ‘marshmallows’ are easily replaced, as Calicat ( Craig ) says. I used a block of wood ( like a 2 X 4 ) to hold the window in the ‘up’ position, while I removed the motor from the regulator ( just to be safe ). Technically the spring is what holds the window in the up ( default ) position, that is why it ‘seemed’ to work when powering the window up. When you are using the motor to bring the window down, you are working against the spring - hence if the nylon bushings are worn, the motor will just spin and the window won’t go down. These little bushings serve two functions :

(1) When the window reaches the top of its travel ( as determined / pre-set by the window stops and the rubber seal ) - the gear in the motor will begin to deform the nylon bushings and free-wheel around them, sparing the motor from generating more force / burning out and possible forcing the window out of it’s bonded channel ( 1969 style ) - trust me, I’ve seen this happen !

(2) A safety ‘override’ ( over-riding clutch ? )- if something is caught in the window ( a kids arm, for example ), the motor will still keep running ( just as in case #1 ), but once the force of the motor begins to deform the little bushings ( when the kids arm generates sufficient resistance to the motor - just like the window stops ) the drive gear in the motor will again begin to spin around, and no longer create more pressure - preventing crushing or breaking the arm bone.

Remember when you open up the motor, very often the little nylon ‘marshmallows are toasted’ ( broken up, actually ). Especially if you live in a really hot location - they just disintegrate. Make sure you get all the bits out, and inspect the actual gear and the metal teeth on the top of the gear ( looks just like a starter motor Bendix drive gear ! ).

If you have gone to all this trouble, you might as well replace everything, not just the little bushings - it just makes time-sense.

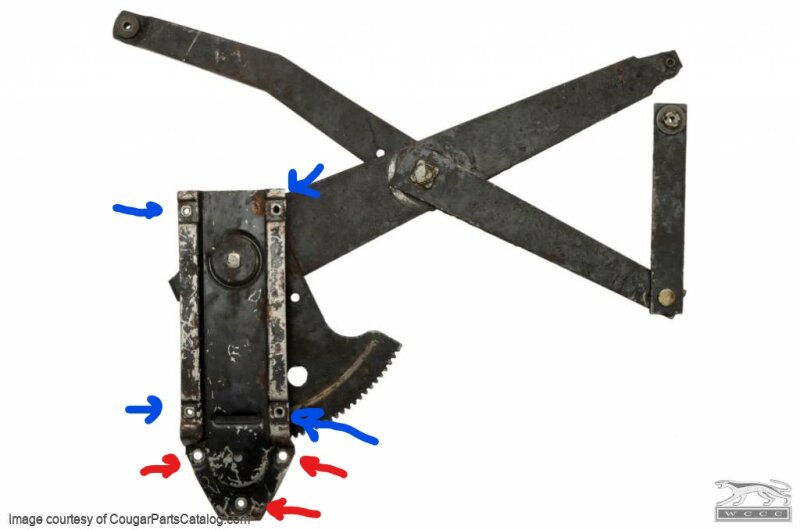

You can get the gear and plate kit at WCCC - item # 32190 ( for $ 29.84 ) :

or just the pins ( Item # 10721 for $ 3.87 )

As to the grease to use, WCCC has Item #: 14-0012 a brake and window mechanism grease.

I haven’t used this so I can’t speak to its effectiveness, but the original FoMoCo power window gear kits contained a bottle of dark ( molybdenum ? ) grease for this purpose. Since I’ve only ever used the original Ford kits, I really can’t recommend the ‘corrrect’ type of grease to use.

The original Ford gear kit was p/n : DOAZ-62234A24-B and there are two on eBay right now ( listing : 165141387074 ) for $49.99, and listing # 274749299022 for $ 30.00 !

Buying an NOS kit would ensure that you DON’T have a problem with the diameter of the little nylon / delrin bushings and you get the proper lubricant !